Microstereolithography: Advancing Precision Manufacturing through High-Resolution 3D Printing

About Course

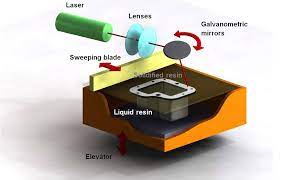

Unlock the future of precision manufacturing with Microstereolithography: Advancing Precision Manufacturing through High-Resolution 3D Printing. This immersive course takes you into the fascinating world of micro-scale 3D printing, where light and liquid resin converge to create structures invisible to the naked eye, yet powerful enough to revolutionize industries from healthcare to aerospace. With technology advancing at nano-speeds, understanding microstereolithography isn’t just a skill — it’s a competitive edge.

Through captivating case studies, interactive learning modules, and real-world applications, you’ll gain hands-on insights into the science, engineering, and innovation behind microstereolithography. Whether you’re curious about medical implants, intricate jewelry, or microfluidic systems for lab-on-a-chip applications, this course is your gateway to mastering high-resolution additive manufacturing and contributing to cutting-edge technologies.

Course Content

I. Introduction to Microstereolithography

Definition and principles of microstereolithography

00:00Importance of high-resolution 3D printing in precision manufacturing

00:00Overview of the ebook’s contents and objectives

00:00