Illuminating Innovation: Laser Applications in Materials Science

About Course

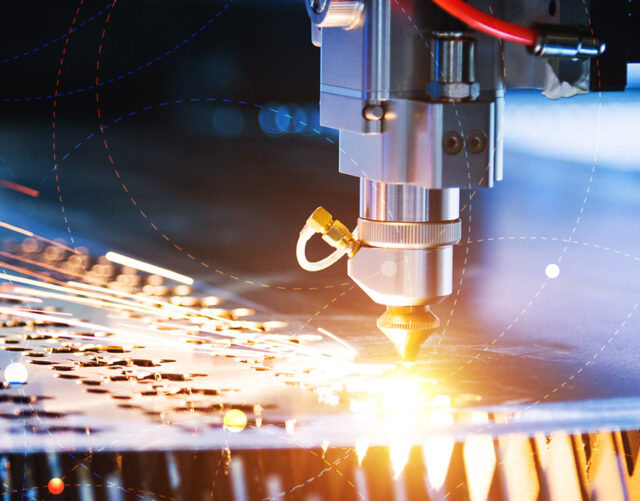

Welcome to Illuminating Innovation: Laser Applications in Materials Science, a dynamic and immersive course designed to unveil the powerful role lasers play in shaping the future of materials engineering. From the cutting floor of aerospace factories to the nanoscale labs driving quantum devices, lasers are precision tools that transform, manipulate, and enhance materials in ways that were once science fiction. This course bridges the gap between theory and real-world applications, making complex laser-material interactions both accessible and inspiring.

Whether you’re fascinated by the ability of lasers to slice through titanium with surgical precision or intrigued by how they enable the creation of ultra-lightweight 3D-printed alloys, this course will light up your understanding of how laser technology is revolutionizing manufacturing, healthcare, environmental monitoring, and more. Packed with case studies, hands-on insights, and forward-looking innovations, you’ll gain a deep appreciation for how beams of light are building the materials of tomorrow.

Course Content

Introduction

The significance of lasers in materials science

00:00Overview of the ebook’s content

00:00