The Future of Manufacturing: 3D Printing Technology, Applications and Market Trends

About Course

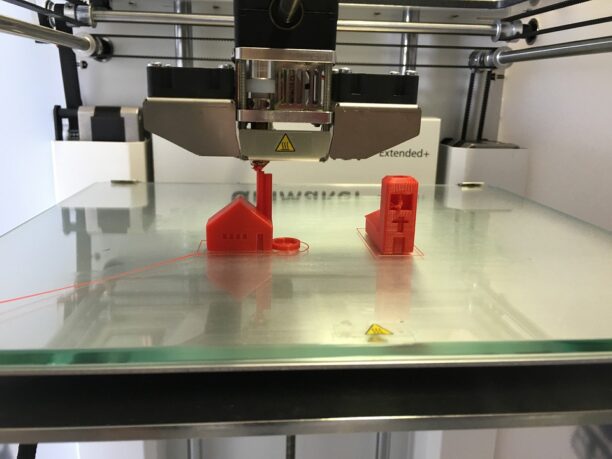

Step into the future of manufacturing with this immersive course on 3D printing technology. Whether you’re a student, a design enthusiast, or a working professional, this course introduces you to one of the most transformative innovations of the 21st century. From simple prototyping to the creation of aerospace parts and biomedical devices, 3D printing has evolved into a powerful tool redefining how products are designed, built, and delivered.

Through rich visuals, interactive learning, and real-world examples, you’ll uncover the science behind additive manufacturing, understand how the design-to-print pipeline works, and explore various types of 3D printers and materials—including metal-based printing. You’ll also learn about quality control, emerging standards, and the current challenges industries face while adopting 3D printing at scale. The course concludes with a deep dive into diverse applications and market trends, giving you the knowledge to critically assess where 3D printing is headed and how it can shape your career or business strategy.

Course Content

Introduction

What is 3D printing?

00:00