Unlocking the Future: A Comprehensive Guide to Industry 4.0 Technologies

Course Content

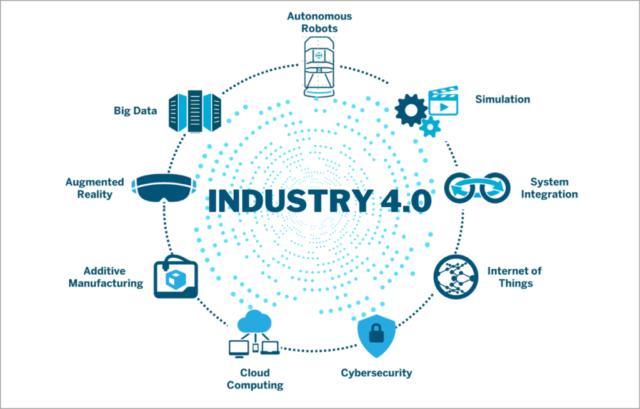

Introduction to Industry 4.0

-

The significance of Industry 4.0 in shaping the future of industries

00:00 -

Understanding the core principles and pillars of Industry 4.0

00:00 -

The transformative potential of Industry 4.0 technologies

00:00